- Product summary: Coal slurry drying equipment is a specialized device used for drying coal slurry, suitable for multiple industries such ...

- Contact Number: 86-19516399666 Mr. Xu

![]() Factory direct sales

Factory direct sales

![]() Professional team

Professional team

![]() Quality assurance

Quality assurance

![]() Win win cooperation

Win win cooperation

Product details

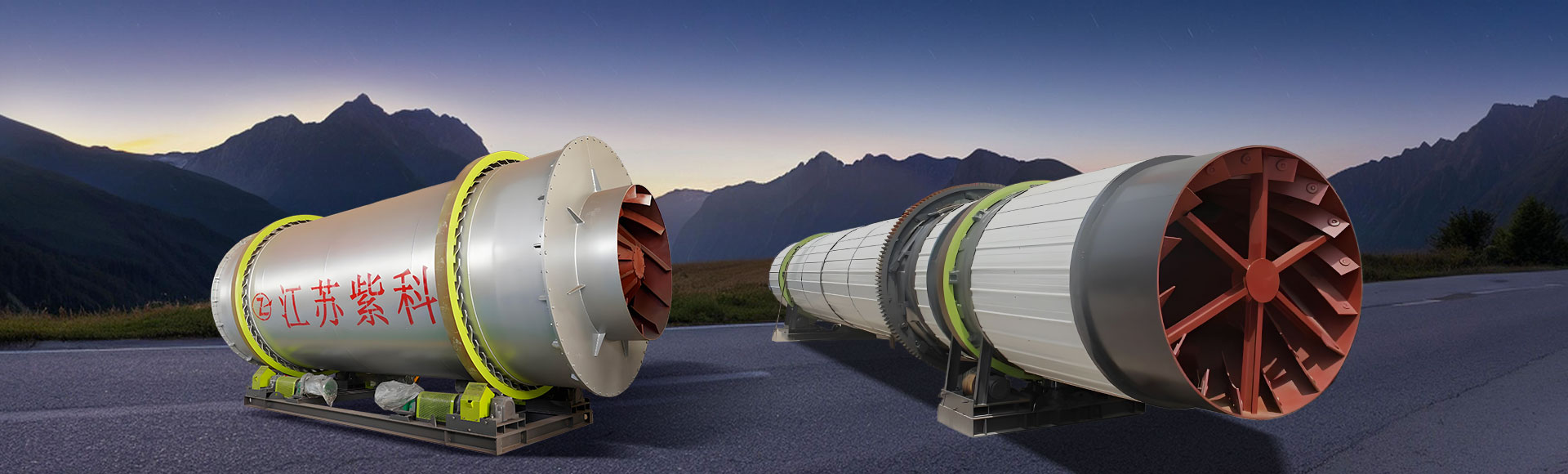

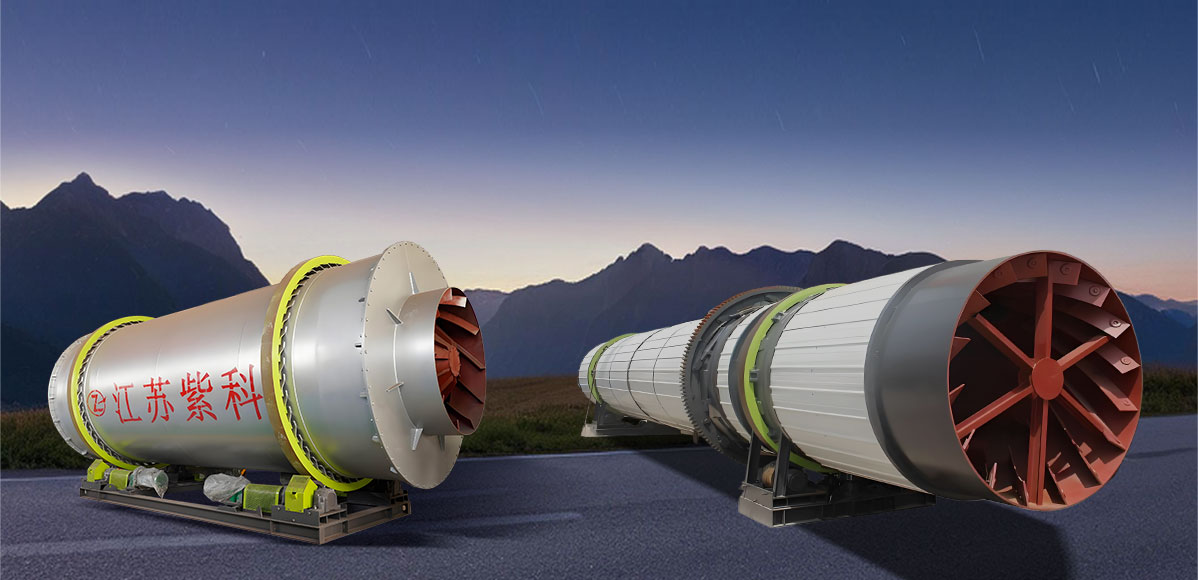

Coal slurry drying equipment is a specialized device used for drying coal slurry, suitable for multiple industries such as coal slurry, sludge, magnetic, heavy, and floating concentrates of metal and non-metal ores in the coal mining industry, and clay in the cement industry.

working principle

The working principle of coal slurry dryer mainly includes the following steps:

Feed: Coal slurry is sent to the hopper through a belt conveyor or bucket elevator, and then enters the feed end of the dryer through the feeding pipeline.

Drying process: Wet materials enter the cylinder of the dryer and undergo mass and heat exchange with high-temperature flue gas to complete the drying of the materials. The dried material is discharged through a cyclone separator, with a portion entering the block pressing system for compression into blocks, and another portion entering the fuel feeding device for combustion to form high-temperature flue gas, which is used as the heat source for the entire drying system.

Discharge: The dried material is discharged through the discharge damper to complete the entire drying process.

Structural composition

The coal slurry dryer mainly consists of the following parts:

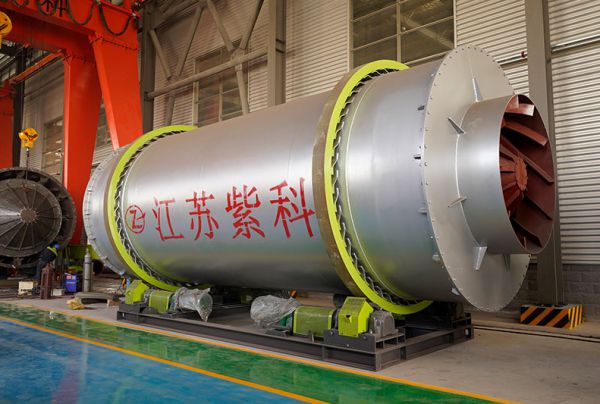

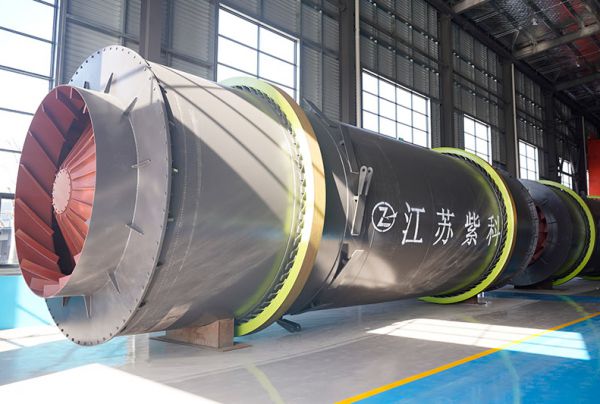

Drum: The drum is the core component of the dryer, equipped with mixing or lifting plates inside, used to disperse wet materials and fully contact with hot air to evaporate moisture.

Transmission device: including motor, reducer, and coupling, which drives the drum to rotate and evenly heat the material.

Heat source system: including burner and hot blast stove, providing high-temperature heat source.

Discharge mechanism: Control the outflow speed and quantity of materials to prevent clumping or excessive drying.

Exhaust system: including fans and exhaust pipes, to discharge water vapor and exhaust gas during the drying process.

Control system: such as PLC control system and touch screen, monitoring and controlling the stability and safety of the drying process.

- Previous:Coal slime dryer

- Next:Coal foam upgrading

Related products