- Product summary: The coal drying production line is an industrial equipment specifically designed for processing wet coal materials. Thro...

- Contact Number: 86-19516399666 Mr. Xu

![]() Factory direct sales

Factory direct sales

![]() Professional team

Professional team

![]() Quality assurance

Quality assurance

![]() Win win cooperation

Win win cooperation

Product details

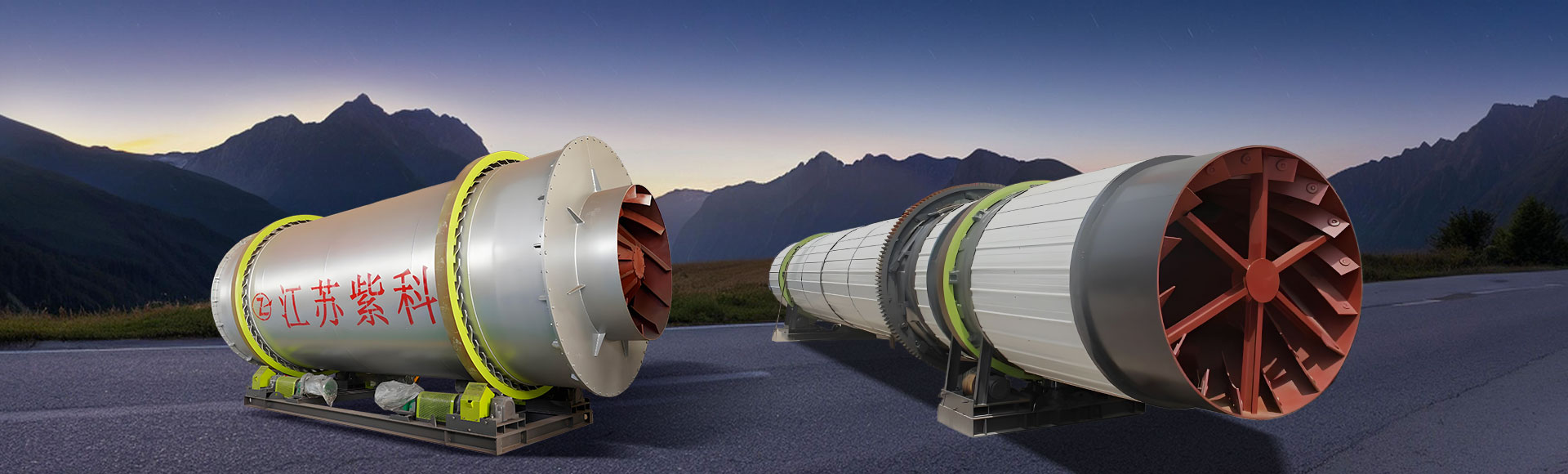

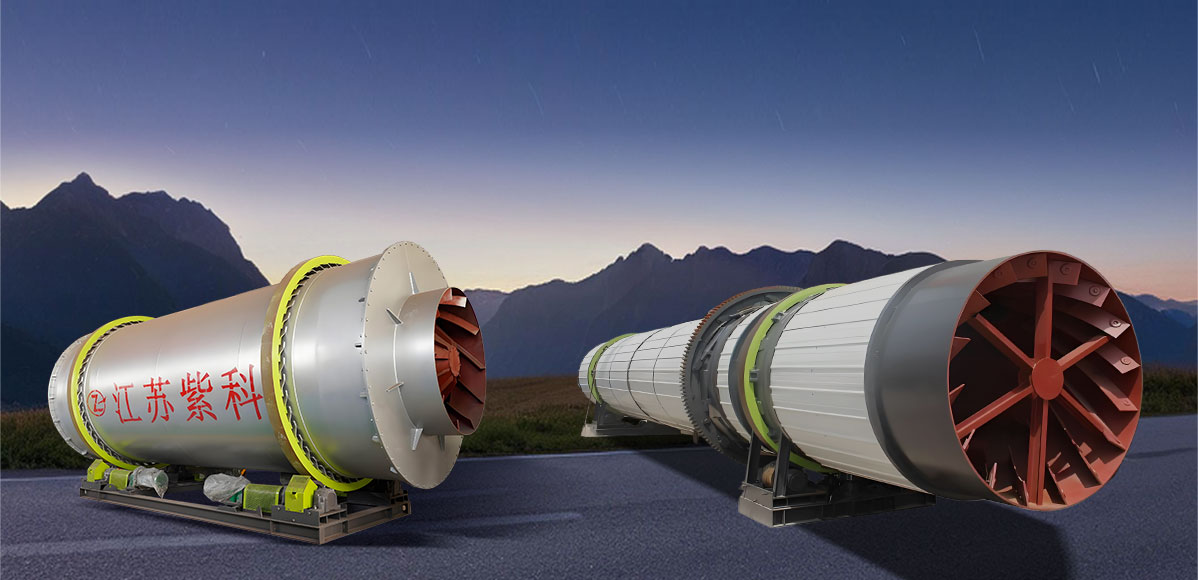

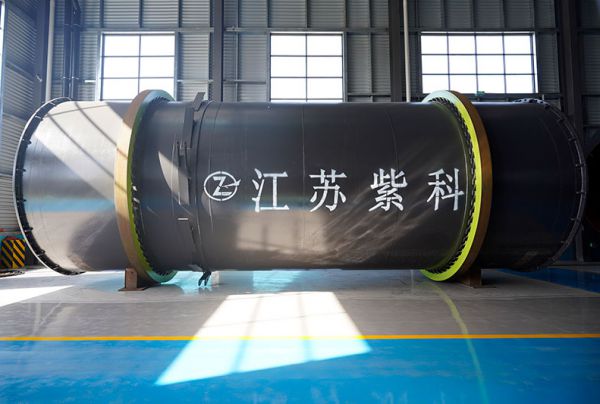

The coal drying production line is an industrial equipment specifically designed for processing wet coal materials. Through a series of process flows, the wet coal is dried to the required moisture content for further processing or utilization.

Component

The coal drying production line mainly consists of the following parts:

Loading and unloading device: used to feed materials into the dryer drum and discharge the dried materials from the drum.

Drying machine host: Coal materials come into contact with high-temperature hot air inside the drying machine drum, greatly reducing moisture content.

Heat source device: generates high-temperature hot air, which enters the dryer drum together with the material, helping to reduce the moisture content of the material.

Dust removal equipment: deals with the dust generated in the production line to ensure a clean environment.

Induced draft fan: Helps circulate hot air in the production line, improving drying efficiency.

Distribution cabinet: controls the operation of the entire production line.

Working principle

Coal materials enter the feeding hopper through a conveyor and then enter the dryer drum. During the continuous rolling of the drum, the coal material is fully contacted with the high-temperature hot air, and the moisture gradually evaporates. The dried coal material is discharged from the discharge port, completing the whole drying process.

Characteristics and application scenarios

Stable operation: The coal dryer can run continuously for a long time with a low failure rate.

Automated control: Easy to operate, only 1-3 people are needed to complete equipment operations, saving manpower.

Energy saving and environmental protection: good sealing, full utilization of heat energy, less dust overflow, and minimal impact on the environment.

Small footprint: The entire production line is compact, with a small footprint and low investment costs.

High efficiency: high processing output and high work efficiency.

Multiple heat sources: Various fuels such as coal, natural gas, steam, etc. can be selected.

- Previous:Complete set of coal drying equipment

- Next:

Related products