- Product summary: Gas box pulse dust collector is an efficient and modular dust removal equipment mainly used for dust treatment in indust...

- Contact Number: 86-19516399666 Mr. Xu

![]() Factory direct sales

Factory direct sales

![]() Professional team

Professional team

![]() Quality assurance

Quality assurance

![]() Win win cooperation

Win win cooperation

Product details

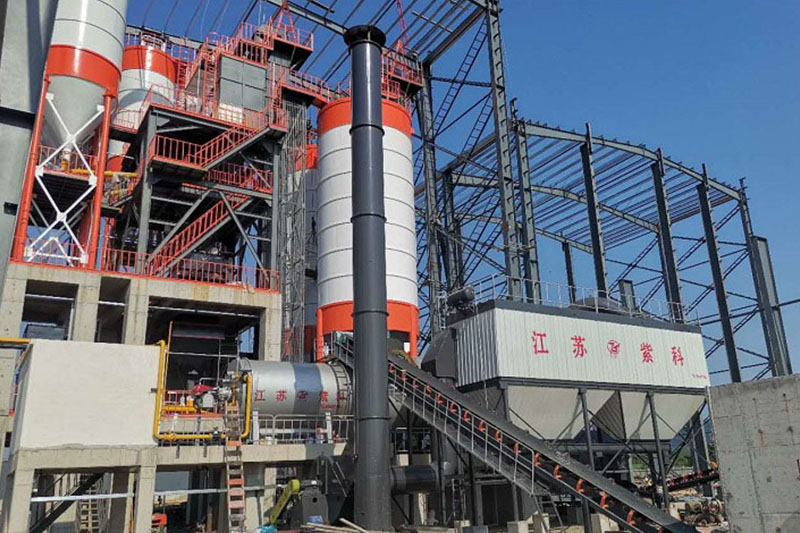

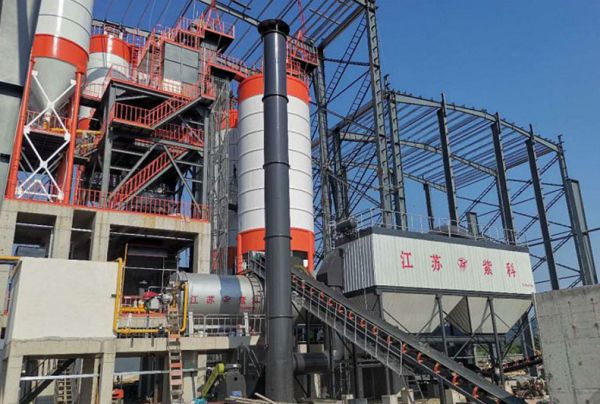

Gas box pulse dust collector is an efficient and modular dust removal equipment mainly used for dust treatment in industrial production. Its core features include high-efficiency filtration, modular design, and strong adaptability.

Structural characteristics and working principle

The gas box pulse dust collector adopts a gas box structure, which is compact in overall structure and occupies a small area. Multiple cloth bags are arranged inside as filter media. The equipment body is divided into several compartments, each containing varying numbers of filter bags. Common configurations include 32, 64, 96, etc. The specific configuration can be adjusted according to actual needs. This modular design facilitates equipment maintenance and management, while improving the stability and efficiency of the dust removal process.

The working principle of the pneumatic pulse dust collector mainly includes two core processes: bag filtration and pulse cleaning:

Bag filter: Dust containing gas enters the dust collector through the intake pipe, undergoes preliminary dust removal by a pre-treatment device (such as a cyclone dust collector or diffuser), and then enters the bag filter area. Dust is captured by the fiber layer on the surface of the bag and adheres to the outer surface of the bag, while clean gas enters the clean air chamber through the bag and is ultimately discharged through the exhaust pipe.

Pulse dust cleaning: As the dust removal process progresses, the dust on the outer surface of the bag gradually accumulates, leading to an increase in bag resistance and a decrease in dust removal efficiency. At this time, the pulse cleaning system is activated, and high-pressure gas is instantly sprayed onto the bag, causing severe vibration and expansion of the bag, thereby shaking off the dust attached to the outer surface of the bag and falling into the ash hopper. After the dust cleaning process is completed, the bag will restore its original filtering performance and continue to be used for dust removal work.

Application Fields and Technical Parameters

Gas box pulse dust collectors have a wide range of applications in multiple industrial fields:

Cement manufacturing: effectively capturing dust generated during processes such as limestone crushing, grinding, and calcination.

Steel smelting: suitable for blast furnace gas purification, sintering ore cooling and other processes, improving energy utilization and reducing harmful gas emissions.

Chemical and pharmaceutical industries: used for powder material transportation, mixing, packaging and other processes to ensure product purity and prevent contamination.

Electricity and Thermal Energy Conversion Department: Achieving ultra-low emission targets in coal-fired power plants.

The pneumatic pulse dust collector has the following technical parameters and performance characteristics:

Processing air volume: Depending on the specific model and configuration, the range of processing air volume is wide.

Filtration efficiency: Efficient filtration, especially suitable for handling fine dust.

Cleaning method: Using a pulse cleaning system to ensure that the filter bag always maintains low resistance and good filtering performance.

- Previous:Pulse bag filter

- Next:Pulse dust collector

Related products