- Product summary: Pulse dust collector is an efficient air purification device that mainly uses pulse blowback technology to remove dust a...

- Contact Number: 86-19516399666 Mr. Xu

![]() Factory direct sales

Factory direct sales

![]() Professional team

Professional team

![]() Quality assurance

Quality assurance

![]() Win win cooperation

Win win cooperation

Product details

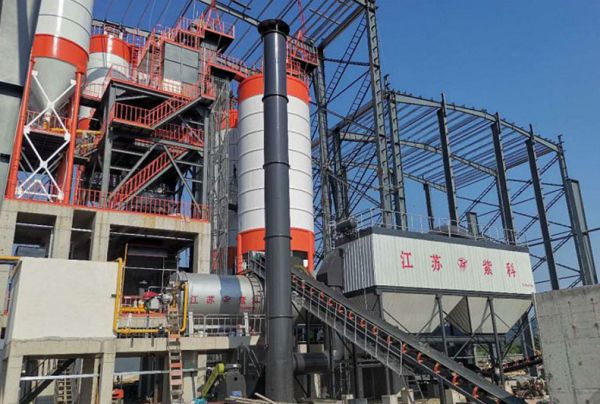

Pulse dust collector is an efficient air purification device that mainly uses pulse blowback technology to remove dust and particulate matter from the air, making indoor air fresher. It compresses the gas to a certain degree through a high-pressure air pump, and then sprays high-speed airflow into the filter bag within a certain time interval, causing the dust particles on the surface of the filter bag to be impacted and fall into the collector. Pulse dust collectors have the characteristics of high efficiency, stability, and reliability, and are widely used in industries such as power, building materials, metallurgy, coking, boilers, and chemical engineering.

The working principle of a pulse dust collector is that the dusty gas enters the equipment through the air inlet. Large particles of dust fall directly in the ash hopper due to inertia and gravity, while small dust particles follow the airflow into the filter bag filtration area and are trapped on the outer surface of the filter bag. After purification, the gas enters the upper box through the filter bag port and is then discharged from the air outlet. Over time, the dust layer outside the filter bag will continue to accumulate, which may increase the resistance of the dust collector and affect the processing efficiency. It is necessary to regularly clean the filter bag to maintain the normal operation of the equipment.

The structure of a pulse dust collector includes an ash hopper, an upper box, a middle box, and a lower box. The upper, middle, and lower boxes are divided into compartments, and the spraying system includes control instruments, control valves, pulse valves, spraying pipes, and air bags. The purification process of dusty gas through the filter bag results in an increasing amount of dust accumulating on the filter bag over time, which increases the resistance of the filter bag. In order to control the resistance within a limited range and ensure the required amount of gas passes through, the control instrument sends instructions to trigger each control valve to open the pulse valve in sequence. The compressed air in the air bag instantly passes through the pulse valve and is sprayed into each hole of the spray pipe, and then sprayed into the corresponding filter bag in the Venturi pipe. The filter bag rapidly expands under the instantaneous reverse action of the airflow, causing the dust accumulated on the surface of the filter bag to fall off, and the filter bag is regenerated.

- Previous:Gas box pulse dust collector

- Next:Air box pulse bag filter

Related products