- Product summary: A dust collector is a device called a dust collector or dust removal equipment that separates dust from flue gas. The pe...

- Contact Number: 86-19516399666 Mr. Xu

![]() Factory direct sales

Factory direct sales

![]() Professional team

Professional team

![]() Quality assurance

Quality assurance

![]() Win win cooperation

Win win cooperation

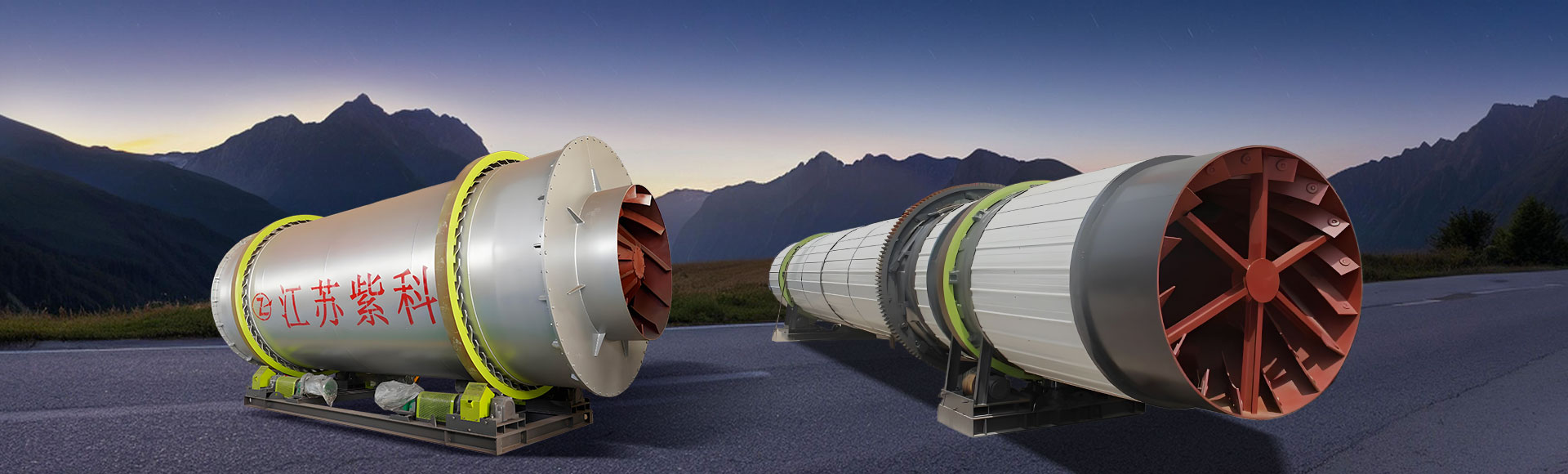

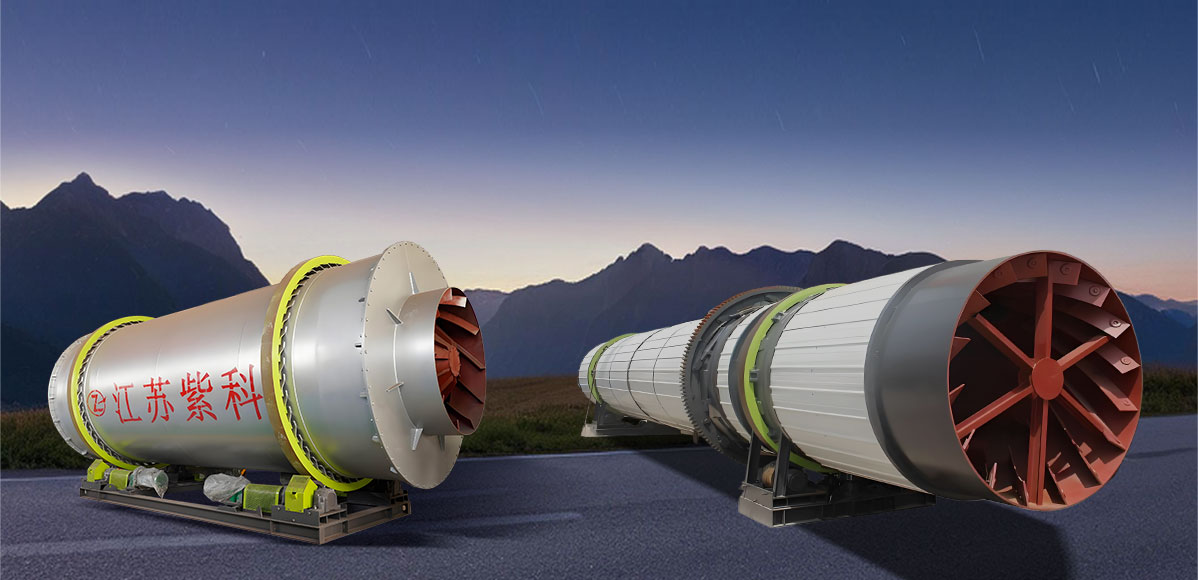

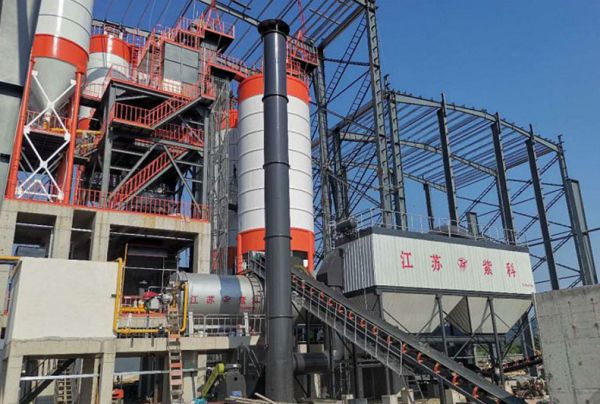

Product details

A dust collector is a device called a dust collector or dust removal equipment that separates dust from flue gas. The performance of a dust collector is expressed by the amount of gas that can be processed, the resistance loss of gas passing through the dust collector, and the dust removal efficiency. At the same time, the price, operation and maintenance costs, service life, and difficulty of operation and management of dust collectors are also important factors to consider their performance. Dust collector is a commonly used facility in boilers and industrial production.

According to the principle of operation, dust collectors can be divided into the following types:

1. Dry mechanical dust collectors mainly refer to dust removal equipment designed for the application of dust inertia and gravity, such as settling chambers, inert dust collectors, cyclone dust collectors, and other high concentration dust collectors. They are mainly used for the separation or concentration of high concentration coarse particle size dust.

2. Wet dust collectors are dust removal devices that rely on hydraulic lubrication to separate and capture dust particles, such as spray towers, scrubbers, impact dust collectors, Venturi tubes, etc. They are commonly used in situations where high concentrations and large air volumes of dusty gases occur during production. The separation efficiency of coarser, hydrophilic dust is higher than that of dry mechanical dust collectors.

3. A granular layer dust collector is a device that uses layers of granular materials with different particle sizes as filter media to block and filter dust contained in the air solution. Mainly used as a dust removal point in the production processes of building materials, metallurgy, etc., it often filters high concentration, coarse particles, and high-temperature dusty flue gas.

4. Bag filter is a dust removal device that uses fiber fabric or filling layer as the filtering medium. It has a wide range of applications, forms, dust removal air volume, and efficiency. It is mainly used in places where fine dust is captured, both in exhaust dust removal systems and intake systems. In recent years, due to the continuous development of new filter materials, the development of fiber filtration technology has also accelerated, new products continue to emerge, and the application fields are increasingly expanding.

5. The electrostatic precipitator is a dust collector that introduces a dusty airflow into an electrostatic field. Under the action of a high-voltage electric field, the gas ionizes, producing electrons and positive ions, which move towards the positive and negative poles respectively. When the dust particles flow through the working electric field, they become negatively charged and move at a certain speed towards the settling plate opposite to their negative charge sign, where they settle and detach from the airflow, and are collected in the electrostatic precipitator. This type of dust collector has high dust removal efficiency, low resistance, and is easy to maintain and manage. It has a similar effect to bag filters in capturing small dust particles.

- Previous:Air box pulse bag filter

- Next:

Related products